Speed, precision, and consistency define success in today’s electronics industry. As product lifecycles shorten and competition intensifies, manufacturers and engineers increasingly rely on turnkey PCB fabrication and assembly to bring products to market faster without sacrificing quality or control.

Instead of coordinating multiple suppliers for boards, components, and assembly, turnkey manufacturing centralizes the entire workflow under one expert provider. The result is a streamlined, dependable, and cost effective path from digital files to fully assembled, test ready circuit boards.

This guide explains how turnkey PCB manufacturing works, why it matters, and how to choose the right full service electronics partner.

What Does Turnkey PCB Fabrication and Assembly Mean?

Turnkey PCB fabrication and assembly is a comprehensive manufacturing model where one supplier manages the entire electronics production process. This includes:

- PCB fabrication

- Component procurement

- SMT and through hole assembly

- Inspection and testing

- Final packaging and delivery

The term turnkey reflects simplicity: customers submit their design files, and the manufacturer delivers completed boards ready for integration or testing no additional coordination required.

Unlike consigned or kitted assembly, where customers source and ship parts themselves, turnkey manufacturing eliminates logistical complexity and reduces the risk of delays or mismatched components.

Why Turnkey PCB Assembly Is the Smart Choice

Faster Project Timelines

Working with multiple vendors often leads to miscommunication and schedule gaps. A turnkey provider aligns fabrication, sourcing, and assembly into a single timeline, significantly shortening turnaround times especially for prototypes and urgent builds.

Consistent Quality Control

When one manufacturer oversees the entire process, quality checks are integrated at every stage. Design reviews, in process inspections, and final testing ensure every board meets functional and reliability requirements.

Cost Transparency and Efficiency

Turnkey manufacturers source components directly from authorized distributors, reducing procurement costs and minimizing the risk of counterfeit parts. Bulk purchasing power and fewer shipping steps also help control overall project costs.

Inside the Turnkey PCB Manufacturing Workflow

1. File Upload and Engineering Review

The process begins with submitting Gerber files, BOM, pick and place data, and assembly drawings. Engineers review the files for manufacturability and provide feedback, pricing, and lead time estimates.

2. PCB Fabrication

Based on project requirements, boards are manufactured using controlled processes. Options include multilayer, HDI, rigid flex, and high frequency PCBs with surface finishes such as ENIG, HASL, or OSP.

3. Component Procurement

All components are sourced from verified global suppliers. Any required substitutions are communicated clearly and approved before production continues.

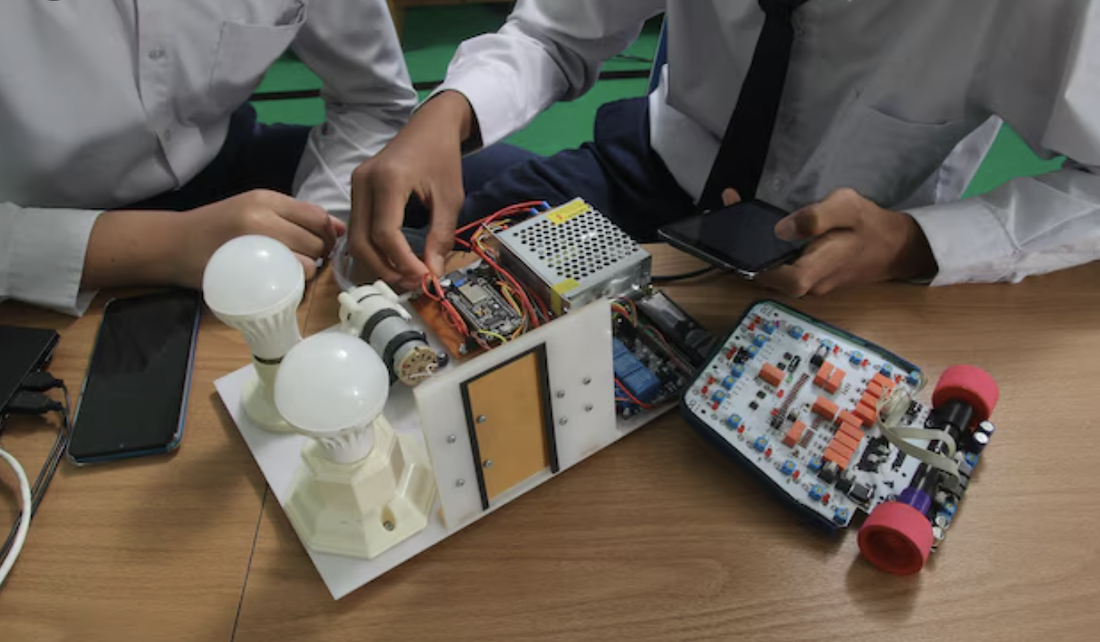

4. SMT and Through Hole Assembly

Automated pick and place machines and precision soldering processes handle everything from standard components to fine pitch BGA, QFN, and 01005 packages.

5. Inspection and Testing

Boards undergo multiple inspection stages, including solder paste inspection (SPI), automated optical inspection (AOI), X ray analysis, and electrical testing. Functional and burn in testing can be added for mission critical applications.

6. Packaging and Global Shipping

Finished boards are carefully packed using ESD safe materials and shipped worldwide through trusted logistics partners.

This integrated workflow reduces errors, improves repeatability, and ensures predictable delivery schedules.

Full Turnkey vs Partial Turnkey Assembly

Full Turnkey Assembly

The manufacturer handles PCB fabrication, parts sourcing, and assembly. This option offers the fastest turnaround, minimal customer involvement, and a single point of accountability.

Partial Turnkey (Kitted Assembly)

Customers supply some or all components while the manufacturer manages fabrication and assembly. While this provides more control over specific parts, it requires additional coordination and inventory management.

For most prototype and small to mid volume projects, full turnkey assembly offers the best balance of speed, reliability, and cost control.

Turnkey PCB Assembly for Medical and Regulated Industries

Medical electronics demand exceptional traceability, compliance, and reliability. A qualified turnkey provider for medical PCB assembly must meet strict regulatory standards such as ISO 13485.

Medical grade turnkey manufacturing includes:

- Component lot tracking and documentation

- Lead free, low residue soldering processes

- In circuit, functional, and aging tests

- Full process traceability and record retention

These safeguards ensure long term performance in critical healthcare and life support applications.

Key Factors That Influence Cost and Lead Time

Several variables affect production timelines and pricing:

- PCB complexity: Layer count, HDI features, and controlled impedance increase manufacturing effort

- Component availability: Long lead time or obsolete parts can delay builds

- Testing depth: Advanced testing improves reliability but adds setup time

- Order volume and urgency: Prototypes move faster; large scale production varies by material availability

Early DFM review and proactive component planning help keep projects on schedule.

Manufacturing Capabilities That Matter

A reliable turnkey electronics manufacturer offers advanced capabilities under one roof, including:

- PCB fabrication up to 50 layers (HDI, rigid flex, heavy copper, RF)

- Precision assembly for micro components and advanced packages

- Quality assurance to IPC Class 2 or Class 3 standards

- Compliance with ISO 9001, ISO 13485, UL, RoHS, and REACH

These capabilities support industries such as medical devices, aerospace, telecom, and industrial automation.

Pre Quote Checklist: What You’ll Need

To receive an accurate and fast quote, prepare the following:

- Gerber and drill files

- BOM with part numbers, footprints, and alternates

- Pick and place (CPL/XY) file and assembly drawings

- Testing and quality requirements

- Shipping preferences and delivery deadlines

Clear documentation ensures quicker reviews and smoother production.

Final Thoughts: Why Turnkey PCB Manufacturing Accelerates Innovation

Turnkey PCB fabrication and assembly removes the friction from electronics manufacturing. By combining design review, fabrication, sourcing, assembly, and testing into one coordinated process, businesses gain speed, consistency, and peace of mind.

From early stage prototypes to full production runs, a trusted turnkey electronics partner helps transform ideas into reliable, market ready products faster and with fewer risks.